目次

名古屋を代表する銘菓といえば、2つの赤提灯がトレードマークの「大須ういろ」です。名古屋の人は学校給食のデザートとして楽しみにしていた方も多いのではないでしょうか。

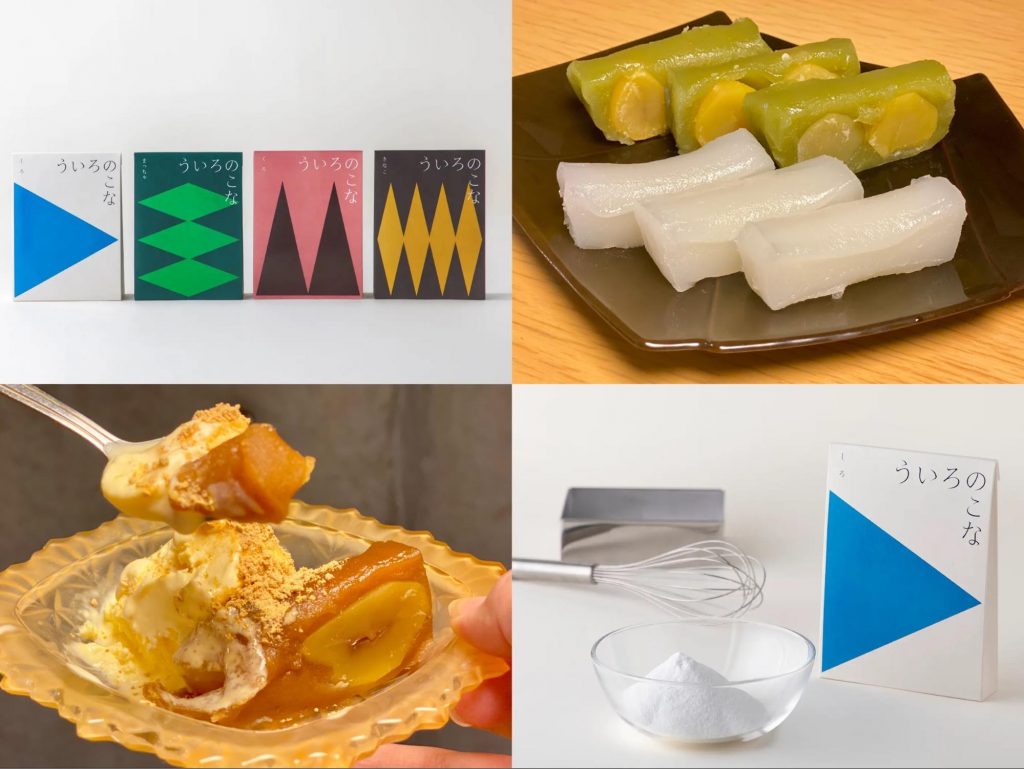

近年では、アイスバーのようなルックスの「ウイロバー」や、モナカの中にういろうが入っている「ういろモナカ」など、斬新な商品開発にも力を入れられています。

そんな大須ういろから満を持して誕生したのが、グルテンフリーの新商品「初-うい」。今回はそんな「初-うい」誕生秘話からヒット商品、さらに大須ういろの歴史、工場見学とたっぷりの内容でお届けしていきます。

大須ういろは1947年(昭和22年)、大須商店街の仁王門通りで創業したのがはじまりです。当初は羊羹を製造してましたが、需要の多いういろうの製造を本格化。現在では直営店をはじめ、300カ所以上で販売されています。

一般的には“ういろう”と呼ばれていますが、大須ういろでは“ういろ”という名称を使っています。また、ういろにこしあんを加えた「ないろ」は大須ういろの専売品で、名古屋では「ういろ」「ないろ」ともに馴染みのあるお菓子として知られています。

そんな、ういろ・ないろの製造工場が、名古屋市緑区にあります。今回は特別に大須ういろができがあるまでの工程を見学させていただきました。

今回、案内していただくのは6代目の村山賢祐社長です。

よろしくお願いします!

米粉の風合いを活かしたこだわりのういろ

まずは「味いろ」の製造を見学させていただきました。味いろは職人さんの手によって丁寧にういろづくりがされています。

村山社長:「ういろの工程はとてもシンプルなんです。米粉と砂糖に水を加えてせいろで蒸す。とってもシンプルだからこそ、味を一定に保つことが難しい商品でもあります。特に大須ういろでは、うるち米の風合いを大切にしており、お米がもっている甘味や香りを大切にしています。季節によっても変わりますし、お米は毎年味が変わるので、素材の微妙な風味を調整して伝統の味をつくるのが職人の腕の見せ所です。」

味いろ

大須ういろでは、機械化している部分もありますが、昔ながらの製造も大切にされています。特にこの「味いろ」では昔ながらの製法でせいろで蒸すところから、最後に切り出す工程まで職人さんによってつくられているのだとか。

この日は素朴で香ばしいきなこういろに、刻み栗を散りばめた黒ういろを重ねた「栗きなこ」をつくられているところでした。一層目を蒸してから、その上に二層目の生地を流し込み、蒸し上がったらさらに三層目を。中でも職人技が光るのが、三層を重ねる工程です。さまざまな工程を経て味いろが完成していきます。

続いては「ひと口ういろ」の製造現場へ。

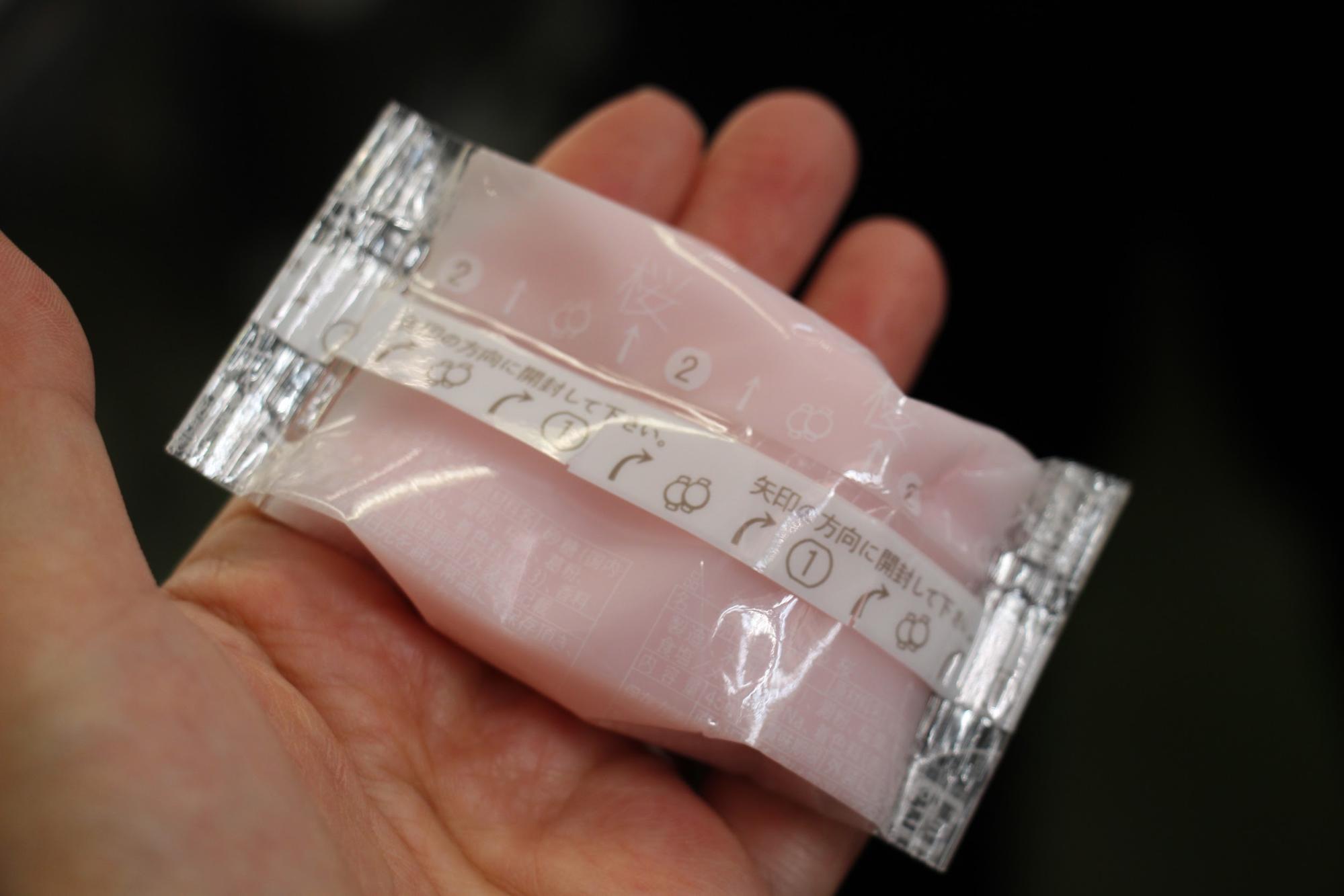

村山社長:「『ひと口ういろ』をつくる上で課題になったのが、ひと口サイズの「フィルム」です。この、フィルムを開発するのに4年の歳月がかかりました。まず重視したのが「切れやすさ」その次に「幅広い温度差」への対応です。ういろ独特のもっちり感を諦めたくなかったので、フィルムの原料を見直しながら、試行錯誤した結果、横切れが良く、ういろが付きにくいフィルムが完成しました。」

「ひと口ういろないろ」

こちらができあがったばかりの一口ういろです。まだとってもあったかいです!

このできあがったういろを職人さんの手によって一つずつ型にはめ込んでいきます。

できあがったういろが流れてきました。製造過程を知るとなんだか愛おしい気持ちになります。

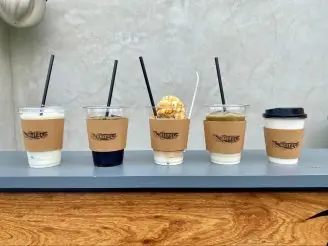

村山社長:「せっかくなので、ぜひできたてのういろを試食してみてください!店頭に並ぶ前のういろは滅多に食べれないですが、これが本当のできたてですよ。」

じゃ〜ん!

こちらが正真正銘のできたてホヤホヤのういろです。とってもぷるぷるで、まだあたたかいんです。いや〜これは最高におしいかったです。

できあがったういろを箱に一つずつ梱包してようやく完成です。職人さんたちが愛情を込めてつくったういろが出荷され、全国の人々に届けられていきます。

定番の「棹ういろ」もこのように並ぶと圧巻です!

実際に工場見学をさせていただくと、いかに手仕事が多いのかを知ることができました。また、季節や気候によって差のでる素材を吟味して使用されており、商品設計に応じて、ベストな形を探って日々カタチにされています。