染物の魅力に触れる。ローカルストーリーを伝える衣料品店「渦〜UZU〜」

目次

「渦〜UZU〜」のものづくり

ここからは、「渦〜UZU〜」のものづくりへのこだわりについてご紹介していきます。

こだわり① 三河エリアの生地を使ったものづくり

三河エリアは、古くから綿織物業が盛んでした。そんな土地柄を生かし、「渦〜UZU〜」では、三河木綿、知多木綿の織元をメインに、自分たちで生地を触り、選定しています。

青木さん:「僕はここ一色町の出身なのですが、昔は糸屋さんとかもたくさんあって、布のロールを積んだ車がよく通っていました。最盛期には、西尾市内だけでも300件以上の機屋さんがあったそうです。最近見ないな〜と思い探してみたところ、現在でも30件ほどの機屋さんで綿生地が織られていました。

近郊にある機屋さんを見つけては飛び込みで訪問し、生地を触らせてもらいました。そして、だんだんと地元の綿素材の良さに惹かれていったんです。現場でお話を聞くうちに、綿生地の歴史や、機屋さんが減少した背景なども教えてもらいました。

「このままではいけない。三河の魅力を発信しよう」と決心しました。そこから、少しずつ素材やデザインを変更し、今はできるだけ三河エリアの生地を使用して、ものづくりをしています。」

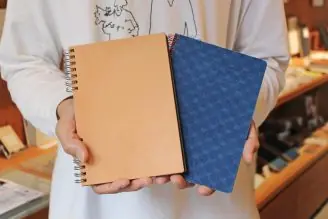

こちらは三河木綿の刺し子織り生地を使用した帽子。

刺し子織りは、柔道着や剣道着、消防用のハッピなどに使われている丈夫な生地です。なんと70年前の織り機で織られているのだそう。現代の織り機と比較してスピードがゆっくりなため、目が詰まりすぎず縫製がしやすいのも特徴。和の雰囲気もあるので「渦〜UZU〜」のデザインと相性バツグンです。

「渦〜UZU〜」のご近所さんの、西尾市吉良町にある「石川メリヤス」で編まれた靴下を染色した、和紙の靴下。サラッとした独特の肌触りで、綿以上の速乾性が特徴です。和紙の糸は、これまで耐久性に問題があったとされていましたが、近年の加工技術の向上と、難しい編み工程をクリアして和紙の靴下ができ上がったそうです。近くに製造元があるからこそ、直接話を聞いて、こうしてストーリーが受け継がれていきます。

こだわり② 手間ひまかけた「植物染め」

渦では、天然染料をメインに染められています。「藍染」「草木染め」「ベンガラ染め」などがあります。どの染め方も、やさしい色味に染め上がります。

青木さん:「うちのアイテムは、植物染料で染めています。手染めによる染色は、短いモノで2〜3日ほど、長いもので1カ月ほどかけて行います。染めて干してを何度も繰り返し、染め重ねることで色味をつくっていくんです。

植物染料は、経年変化により薄くなったり、色味が変化します。長くご愛用いただくために、無料で染め直しもしていますよ。」

藍染

藍染は「沈殿藍(インド藍)」と「すくも灰汁発酵建て(たで藍)」の2種類があります。

・沈殿藍(インド藍)

インドに自生しているマメ科の植物で、インディゴ色素の含有量が高く、染料として世界 的に使用されています。色素を沈殿させ、乾燥し顆粒状にしたものを渦では使用していま す。・すくも灰汁発酵建て(たで藍)

貴重なすくもを原料にし、自然素材のみで行う本格的な発酵建ての藍染。深みのあるやさ しい青が特徴です。毎日少しずつ灰汁を加えながら管理していくので、とても手間と時間 がかかる染料。

草木染め

「玉ねぎ」や「あかね」などの植物をグツグツと煮出して染める「草木染め」。渦では、収穫後に捨てられてしまう、大量の玉ねぎの茶色い皮を、地元の農家さんから引き取り染料にしています。玉ねぎの皮は、やさしい黄色やオレンジ色に染まります。

ベンガラ染め

ベンガラとは、土中の酸化鉄を原料とした天然顔料のこと。本当に土で染めたもの?と驚くほど、きれいな色彩に染まります。

渦では、こうした植物染料での「染め体験」もできますよ!

<渦の選べる 染め体験>

https://read.uzu-japan.com/workshop-page/

最後に今後の展望をお聞きしました。

青木さん:「一番の課題は、機屋さんの高齢化ですね。もうすぐ60歳の方が最年少という機屋さんもあるくらいです。僕たちにできることは、できるだけ地域色を大切に製作し、三河の綿織物の魅力や歴史を伝えることだと思っています。渦をきっかけに、生産者の想いを知っていただけたらうれしいです。」

今回の取材を通して、三河エリアが綿織物業の一大産地ということを知りました。こうした歴史あるものづくりは、守り続けていきたいモノです。渦では、そんな三河エリアの綿素材の魅力や、染色の楽しさに触れることができます。ぜひ訪れてみてくださいね。