目次

1772年創業、昔ながらの製法にこだわったみりんづくりを続ける「九重味淋(ここのえみりん)」。碧南市にある本社では、みりん蔵内部(一部分)に足を踏み入れるガイドツアーや歴史がわかる「九重みりん時代館」、お食事やカフェを楽しめる「レストラン&カフェ K庵」、お買い物ができる直売所「石川八郎治商店」を併設しています。

今回は、九重味淋の魅力をたっぷりとお伝えしていきます。

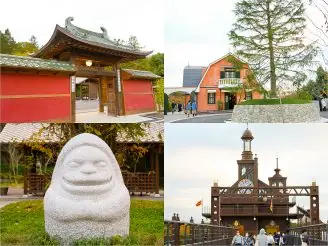

九重味淋があるのは愛知県碧南市。名鉄三河線「碧南」駅から徒歩5分。外観からもその歴史を感じます。

暖簾をくぐると立派な建物がお出迎えしてくれます。2018年に、築200年の創業家の邸宅を改装し「レストラン&カフェ K庵」、直売所「石川八郎治商店」がオープンしました。

江戸時代から続くみりんメーカー「九重味淋」とは?

はじめに、九重味淋の歴史から。

九重味淋が創業したのは、江戸時代1772年(安永元年)のこと。創始者である石川八郎右衛門信敦(石川家第二十二世)が、碧南の地でみりんの製造を手がけたのがはじまりです。

以来、九重味淋では、本みりんづくりに最適な大粒の「もち米」、蔵人の伝承の技が活きた「米こうじ」、清酒造りにも似た醸造方法で丁寧に蒸留した「本格焼酎」を用いて、240年以上に渡りみりんづくりを続けられています。

ガイドツアー&資料館でみりんについて学ぼう

九重味淋のガイドツアーでは工場の一部の見学と、九重味淋やみりんの歴史等の貴重な資料を展示している資料館「九重みりん時代館」の見学ができます。

歴史ある建物に入るのは、なんだか緊張します。

工場の前には顔はめパネルがありました。ついついパネルを見つけると顔をはめてしまいたくなるから、不思議なものです(笑)。

入り口に置いてあるこれはなんだと思いますか?

こちらは「斗甕(とがめ)」と呼ばれる味淋をつめて運んでいた陶器です。一つでもかなりの重量があり一斗缶が使われるまでは、この斗甕で運んでいたというから、驚きです。

また常滑「焼き物散歩道」に見られる土管坂には、この斗甕が埋め込まれているんですよ。言われて見れば、見覚えのある方も多いのではないでしょうか。

集合時間になり、パンフレットと帽子をもらったら見学スタートです。

はじめに、本みりんの製造工程を説明していただきます。

九重味淋のある三河地区は温暖な気候風土、矢作川の水、米などの高品質な農産物。醸造に適した条件と、水運による販路に恵まれて、本みりんづくりが栄えてきました。

ガイドツアーでは一部のみ見学可能ですが、今回は特別にすべてを見せていただきましたよ!

こちらは、圧搾(あっさく)と呼ばれる工程で、原料を混ぜ合わせて2カ月ほど糖化熟成された「もろみ」を酒袋につめている様子です。丁寧につめられたもろみは、2晩かけてじっくりと搾られます。

放冷機

本みりんが完成するまでには、大きく分けて6つの工程が必要です。

①製麴

最初に、良質のうるち米を二昼夜かけて米こうじにする「こうじ」づくりからはじまります。

②仕込み

仕込みでは、主原料である「もち米」を十分に蒸し、大きな釜から少しずつ放冷機で適温に冷やし「米こうじ」を加えます。「米焼酎」と混ぜ合わせたら、仕込みタンクへと送られます。

③糖化熟成

③糖化熟成

もろみが眠るのは、室温18~20度に保たれた蔵の中です。蔵の中には床板を張り、もろみが入ったタンクを半地下の状態に。

こうすることで、温度を安定させ、夏の暑さ、冬の寒さから守るのだとか。蔵人は、タンクのヘリに立ち、竹製の棒「櫂」を使って、8の数字を描くようにもろみを満遍なく混ぜ合わせていきます。糖化熟成は約2カ月かけてじっくりと行います。

④圧搾

④圧搾

3つの工程を経て、先ほど紹介した圧搾の工程へ移ります。糖化熟成した「もろみ」を酒袋に詰め、槽(ふね)と呼ばれる「佐瀬式圧搾機」で搾ります。

はじめはもろみ自身の重みだけで、みりんがじんわりしみだすのを待ちます。その後上から徐々に圧力を加え、2日間かけてゆっくりと搾ります。

⑤貯蔵熟成

搾った本みりんは、1年〜1年半の間、大蔵でゆっくりとねかせます。じっくりと熟成されたみりんは、より深みのある甘さになるんです。蔵のタンクは、床から少し浮かせた状態で置き、上部には木の蓋をかぶせています。地面の温度から直接影響を受けないように底上げし、みりんが呼吸できるよう、木製のふたを使っているのです。

300年の歴史を持つ蔵

九重味淋の大きな特徴でもあるのが、築300年の長い歴史を持つ蔵です。1706年に建築され、1787年に現在の場所へ移築。黒塗総下見板張の土蔵造りで建てられており、柱や梁には太く頑丈な木材が使われています。

蔵には生命力や性質の異なる微生物たちが住んでおり、蔵に息づく微生物は、醸造物の風味や性質に影響を及ぼします。蔵を建て替えれば、どれだけ製法が同じでもみりんの味は異なります。そのため決してこの蔵でなければ九重のみりんはつくれないのだとか。

少しずつ修繕を重ねながら300年以上大切に守り続けられています。

⑥ろ過&出荷

しっかりと熟成されたみりんをろ過することで、黄金色に澄んだ姿を現します。ろ過されたみりんを瓶詰めして、念入りな品質チェックをし、ようやく出荷されるのです。