Toyota Commemorative Museum of Industry and Technology [Part 1]: TripAdvisor's No.1 Factory & Social Studies Tours!

![Toyota Commemorative Museum of Industry and Technology [Part 1]: TripAdvisor's No.1 Factory & Social Studies Tours!](https://life-designs.jp/wp/wp-content/uploads/2019/07/image51-3.jpg)

Table of Contents

Toyota Motor Corporation is one of Japan's leading manufacturers of automobiles, which is leading the world's manufacturing industry. At the Toyota Commemorative Museum of Industry and Technology, you can learn about the history and technology of the Toyota Group, including Toyota Motor Corporation.

Although a "memorial museum" may sounds a bit stuffy, this facility is very popular as a museum that can be enjoyed by children and adults alike! The popularity of the museum is so great that it has been ranked No. 1 for 4 consecutive years in the TripAdvisor's "Travelers' Choice: Factory Tours & Social Studies Tours Ranking"! In recent years, many people from overseas have also visited. Let's take a closer look at the Toyota Commemorative Museum of Industry and Technology, which attracts people from all over the world!

In part 1, we will focus on the The Textile Machinery Pavilion, where you can learn about textile machinery, the cornerstone of the Toyota Group.

What is Toyota Commemorative Museum of Industry and Technology?

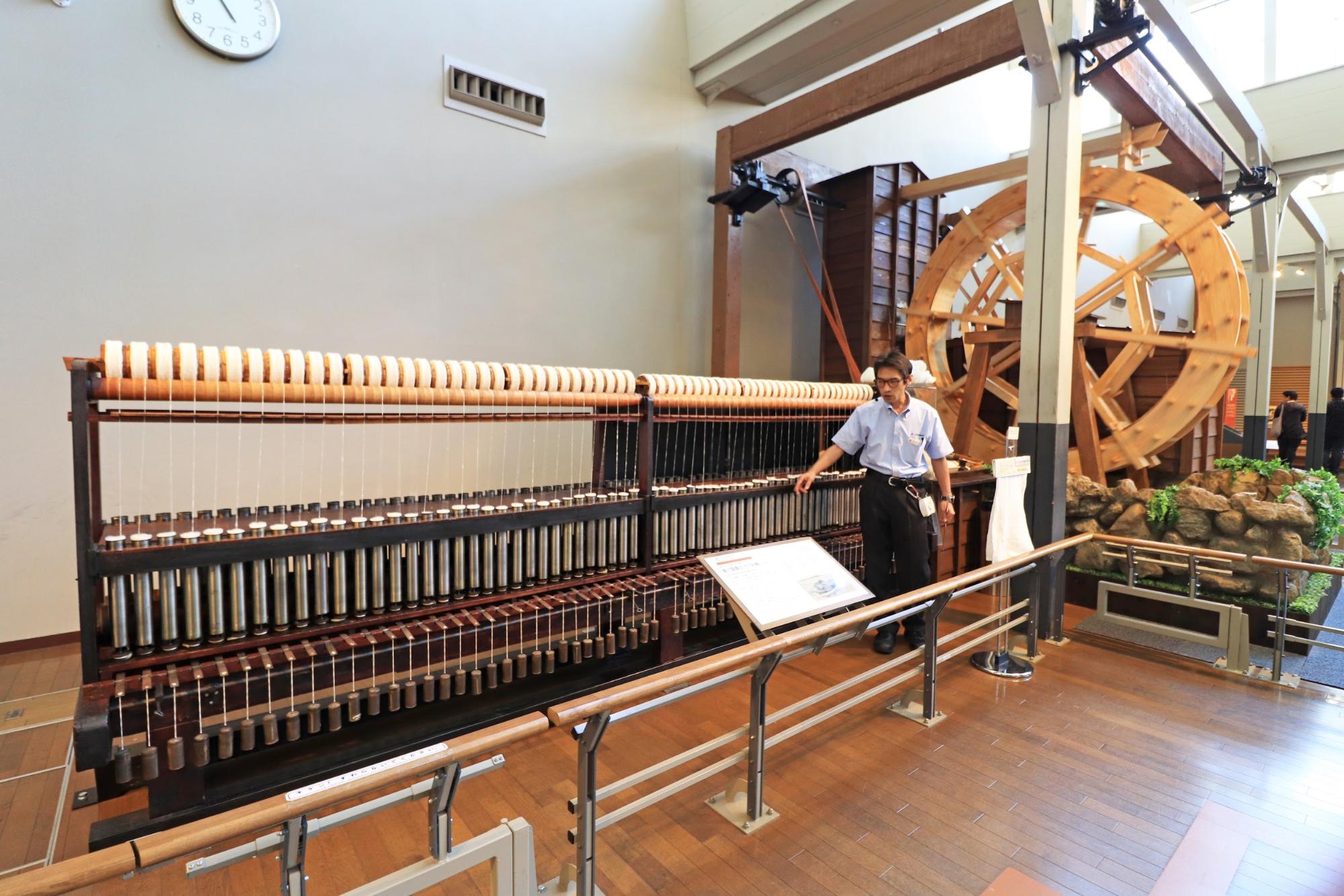

The "Circular Loom" on dynamic display in the lobby as a symbol of the museum

The Toyota Commemorative Museum of Industry and Technology opened in June 1994 in Sakou, Nishi-ku, Nagoya City, which is the birthplace of the Toyota Group. It was built on the site and buildings of a test factory established in 1911 for research and development of weaving machines.

Many people think of automobiles when they hear the word "Toyota," but Toyota actually began in the textile industry. Sakichi Toyoda, the founder of the Toyota Group, devoted his life to the invention of the loom. It was Sakichi's eldest son, Kiichiro Toyoda, who started manufacturing automobiles and founded Toyota Motor Corporation.

The Toyota Commemorative Museum of Industry and Technology is a facility where visitors can learn about the entire history and technology of the Toyota Group, from textile machinery, the foundation of the Toyota Group, to the ever-evolving automotive technology.

No.1 Ranking of

"Factory Tours & Social Studies Tours"

4 Years in a Row!

The Toyota Commemorative Museum of Industry and Technology has been ranked No. 1 for four consecutive years in the "TripAdvisor: Travelers' Choice: Factory Tours & Social Studies Tours" by TripAdvisor, the world's largest travel site!" by TripAdvisor, the world's largest travel site.

It was also ranked 23rd in the "Ranking of Japan's Most Popular Tourist Spots for Foreigners 2018," and is the only place in Aichi Prefecture to make the list. It is a popular spot not only within Japan but also from overseas.

Toyota's Beginnings in Textile Machinery

"The Textile Machinery Pavilion"

The museum has two exhibition halls: the The museum has two exhibition: the Textile Machinery Pavilion and the Automobile Pavilion. First, let's visit the Textile Machinery Pavilion, where you can learn about Toyota's beginnings in textile machinery!

In the Textile Machinery Pavilion, approximately 100 machines from early spinning and weaving tools to modern textile machinery are exhibited in a spacious area of about 3,500 square meters. Visitors can not only look at the machines but also enjoy learning about them by listening to the sounds of the machines and detailed explanations through demonstrations and dynamic displays by the staff.

Learning by Demonstration! Development of Spinning Machine Technology

"Yarn Spinning" to Learn the Principle of Yarn Making

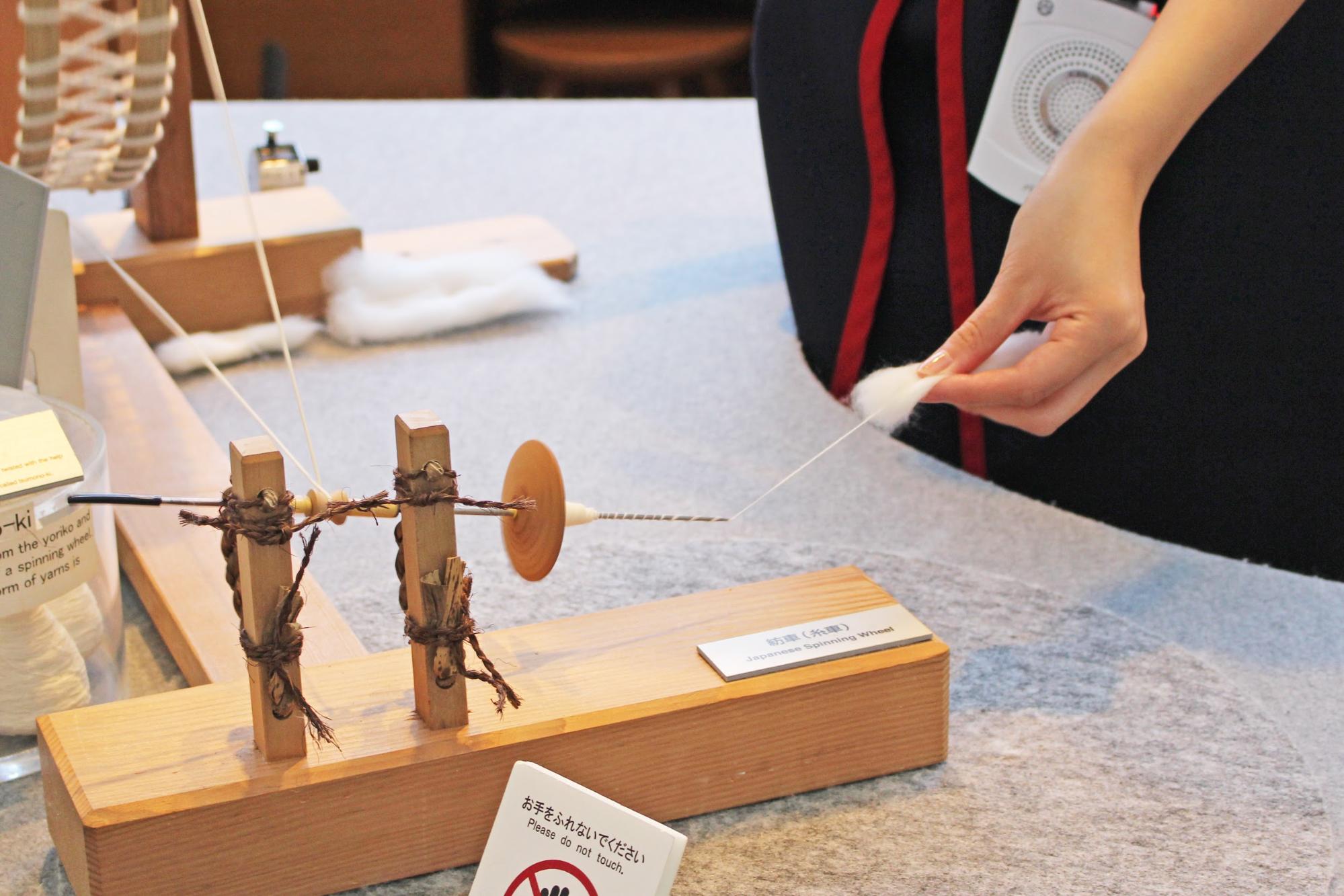

Yarn spinning demonstration

Now let's take a look at the demonstration.

Just after entering the Textile Machinery Pavilion, there was a demonstration of "yarn spinning," using old tools to make yarn from cotton.

Using a "cotton churning wheel," the seeds are removed from the dried cottonseeds.

Vibrating the strings of the "cotton striking bow" loosens the cotton fibers, making them easier to spin. Cottons are now fluffy.

Finally, the fibers are pulled out of the cotton using a spinning wheel and twisted into yarn, which is then wound up. This completes the yarn. In the Edo period, yarn was spun one by one by hand in this way.

It is said that humans first wove cloth before 5,000 BC, but the basic processes of spinning and weaving remain the same today. Technology has advanced in terms of how to make this process faster and more efficient.

Make Many Yarns at Once, "Garabo Throstle Spinning Machine"

In the early Meiji period (1868-1912), the Garabo Throstle Spinning Machine, which could spin dozens of yarns at a time simultaneously, was introduced. The machine was invented by Tokimune Gaun, an engineer from Shinano (present-day Nagano Prefecture).

The machine is said to be called a "Garabo" Throstle Spinning Machine because of the "gara-gara" rattling sound it makes during operation. Here, too, visitors can see the machine in action.

On a Garabo Throstle Spinning Machine, the beaten cotton is made into a rod-shaped "yoriko" and placed in a jar. The cotton is pulled out of the jar and twisted by spinning the jar, turning the cotton into yarn.

Next to it is a replica of a hand-spun Garabo Throstle Spinning Machine. Here, visitors can actually spin the handle to experience yarn making.

Adopting Western Technology "Development of Spinning Machine Technology"

Cotton used for spinning

When the hand spinning machine was invented in Japan, England was already using a machine spinning system to produce good yarns in large quantities. Japan introduced the technology from the West. Cotton spinning machines introduced from the West were largely mechanized and consisted of five main processes.

① "Cotton Mixing" Mixing Cotton and Unraveling Fibers

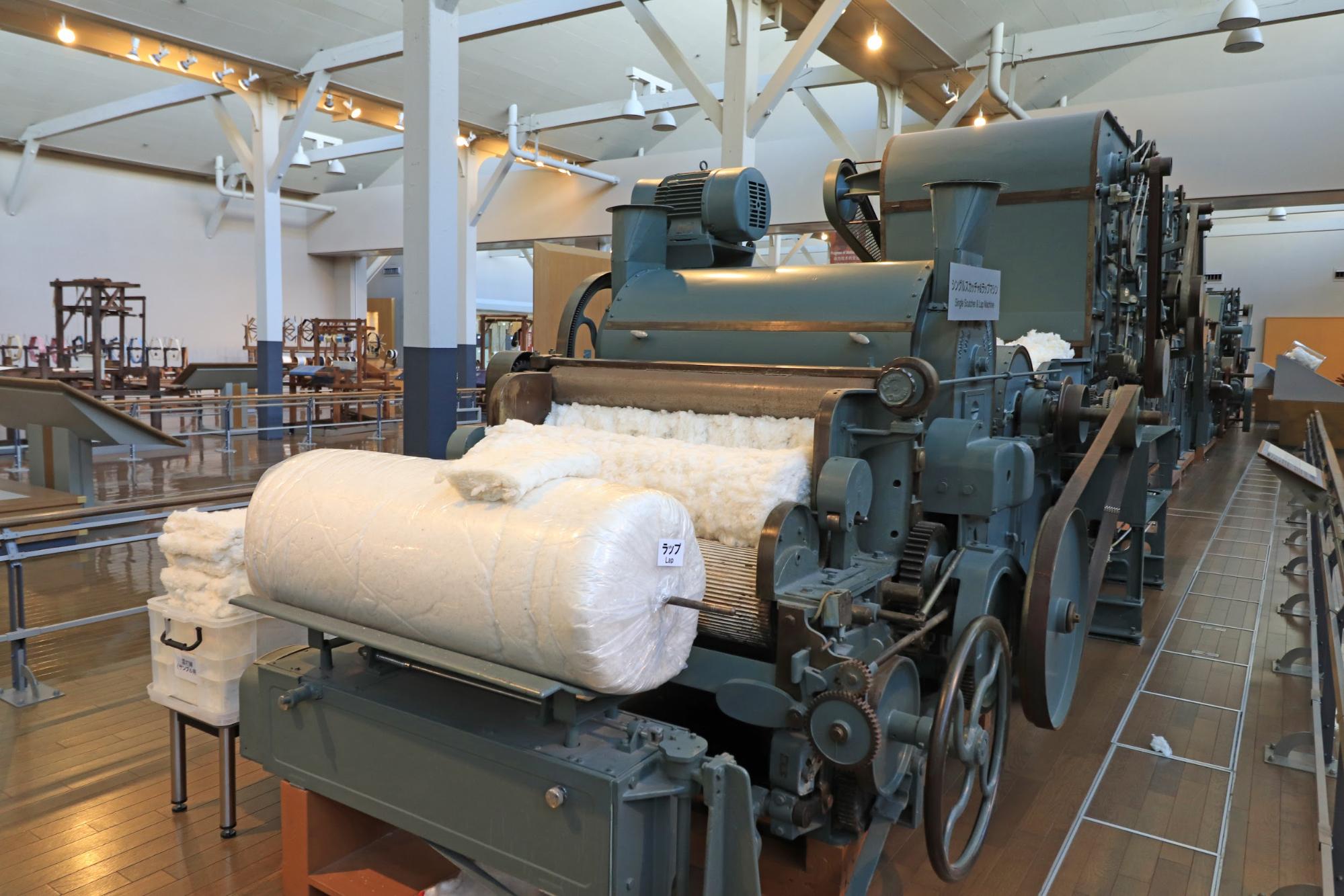

Cotton Mixing Machine

Sheet-like "wrap"

The first process is "cotton mixing " (konda-men).

Several types of raw cotton are torn into small pieces, placed on a conveyor, and mixed in a machine. The cotton is then broken into small pieces and dust is removed to create a sheet-like "lap."

② "Cotton Combing" Combing Fibers

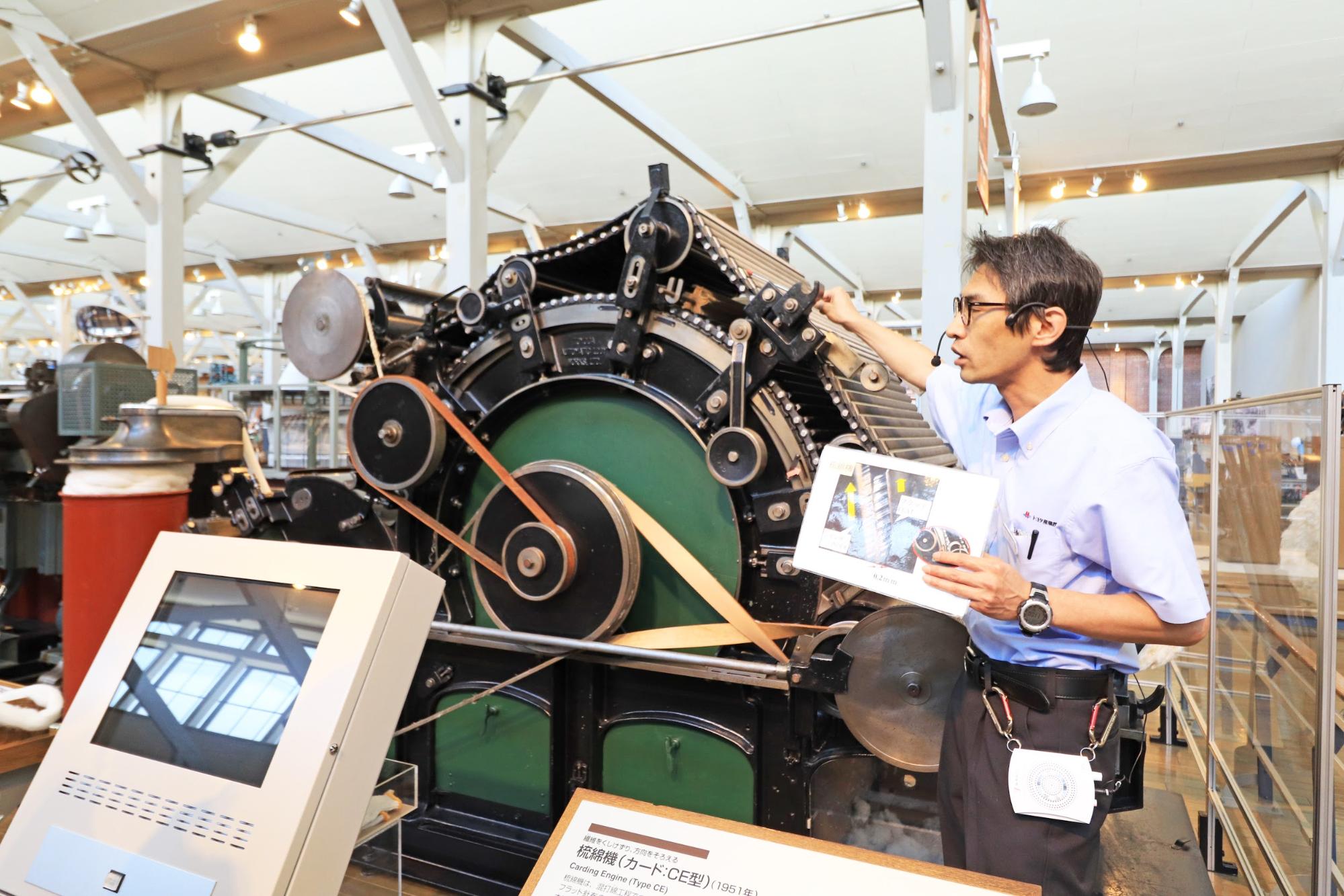

carding machine

card cloth

The next step is the "cotton combing" process.

The lap made earlier is passed between a cylinder rotating at high speed and a continuous needle cloth. The cotton is combed to align the fibers parallel to each other and remove any small particles or short fibers that could not be removed by the cotton blender.

The cotton that comes out is collected and made into ropes called "slivers". It is becoming quite fluffy!

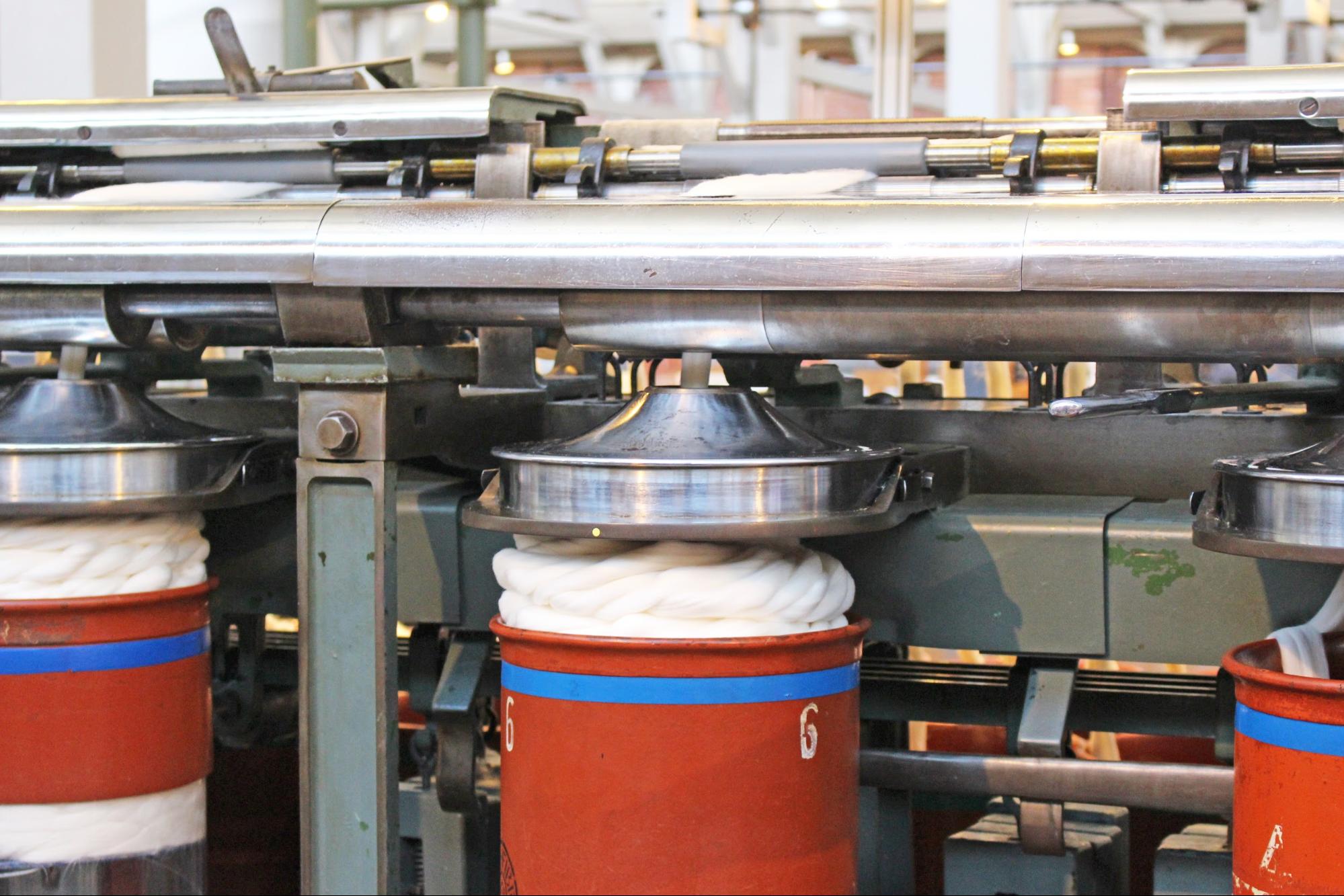

③ "Kneading" Stretching Fibers

kneading machine

In the kneading process, multiple slivers are stretched to uniform thickness to produce high quality yarn. At the same time, the direction of the fibers is aligned. Yarns such as "50% cotton, 50% polyester" are made by combining slivers of different materials at this stage.

It has become quite thread-like, but the fibers still unravel when pulled.

④ "Rough Spinning" Further Stretching and Slight Twisting of the Fibers

spinning machine

The sliver is further stretched and twisted on a coarse spinning machine to produce coarse yarn.

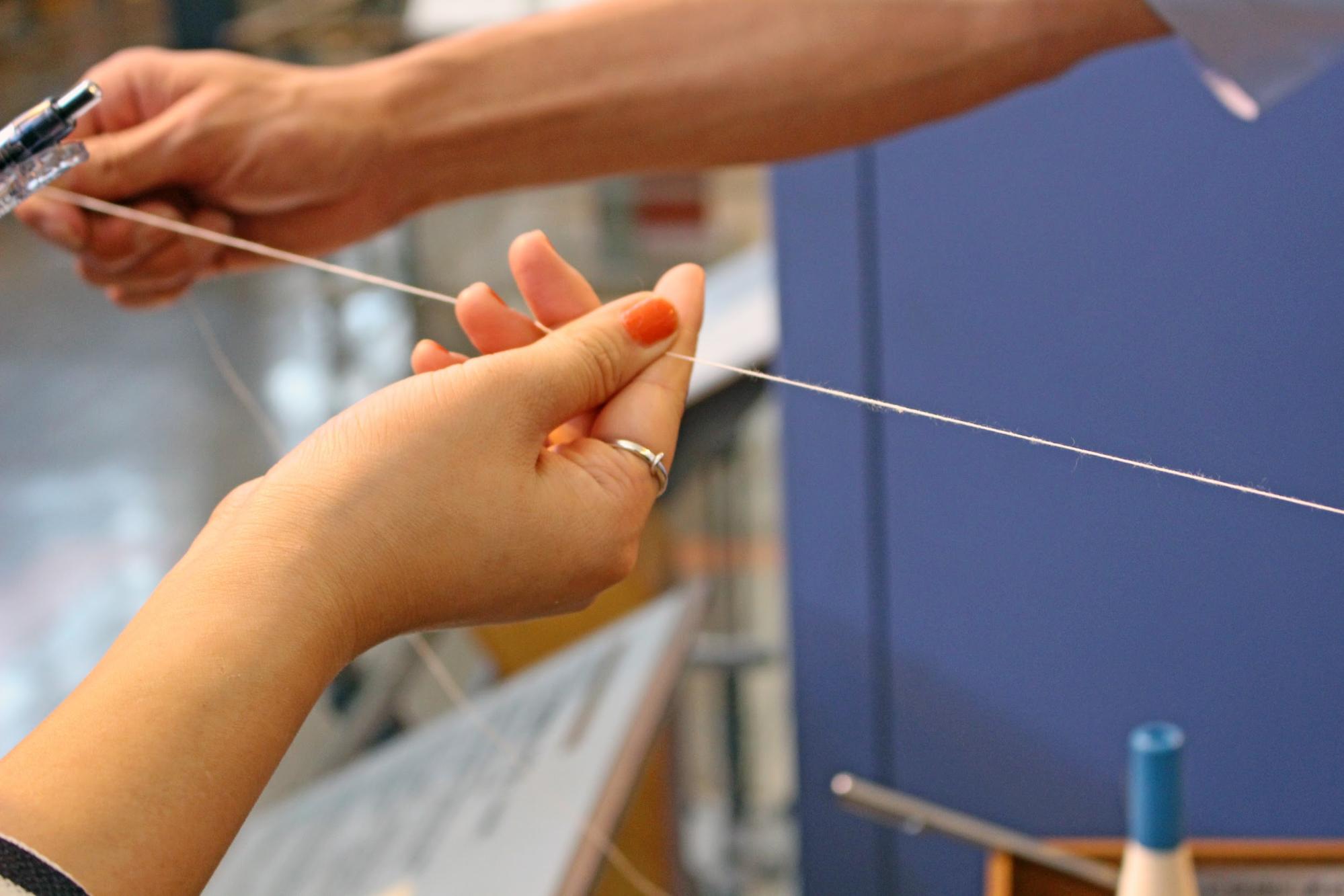

⑤ Spinning: Completion of Yarn

spinning machine (the ring spinning machine on display was manufactured by Toyota Industries Corporation in 1955)

Finally, the coarse yarn is further stretched and twisted in a spinning machine to produce yarn.

After five processes, the yarn is completed!

We were able to see the machine in action, and the staff provided easy-to-understand explanations, so we were able to learn while having fun. The principle of spinning is the same as that of yarn spinning, which we saw demonstrated at the beginning of the tour, but it was amazing to see yarn being spun at an eye-popping speed.

![Toyota Commemorative Museum of Industry and Technology [Part 1]: TripAdvisor's No.1 Factory & Social Studies Tours!|Going out to Meieki, Nakamura-ku, Nagoya|Life Designs|Traveling and Living in Nagoya, Aichi, Gifu and Mie](https://life-designs.jp/wp/wp-content/themes/wp-templ/assets/img/common/logo.svg)

![[Industrial Museum & Factory Tour] Learn the Manufacturing in Tokai Area!](https://life-designs.jp/wp/wp-content/uploads/2019/06/w1920x1088_factory-1024x580.jpg)

![[Tsu City, Mie] A thorough Report on Baby Star Crispy Noodle Snack Themed-park "Oyatsu Town"!](https://life-designs.jp/wp/wp-content/uploads/2019/11/image29-7-300x200.jpg)

![Toyota Commemorative Museum of Industry and Technology [Part 2]: TripAdvisor's No.1 Factory & Social Studies Tours!](https://life-designs.jp/wp/wp-content/uploads/2019/07/image16-20-300x187.jpg)

![[2025 Latest Edition] 7 beer gardens in Nagoya you want to visit this summer!](https://life-designs.jp/wp/wp-content/uploads/2024/07/image11-7-1024x768.jpg)

![[2025 Latest Edition] 7 beer gardens in Nagoya you want to visit this summer!](https://life-designs.jp/wp/wp-content/uploads/2024/07/image11-7.jpg)

![[Indoor Facilities] Where to Go on Rainy Days in Tokai Area! For Family Outings!](https://life-designs.jp/wp/wp-content/uploads/2023/07/FotoJet-23.jpg)

![[Special Feature] Enjoy Your Day at a Park!](https://life-designs.jp/wp/wp-content/uploads/2019/12/LD_banner_w1920x1088_park-1-768x435.jpg)

![[Nagoya-meshi] Nagoya's Speciality Dishes](https://life-designs.jp/wp/wp-content/uploads/2022/06/5ba2ca8c038fd4af7527bc0826367cfb-768x435.png)

![[Special Feature] Enjoy Outdoor Activities!](https://life-designs.jp/wp/wp-content/uploads/2019/12/LD_banner_w1920x1088_outdoor-1-1024x580.jpg)

![[Sauna Specials] Feel Revitalized in Sauna!](https://life-designs.jp/wp/wp-content/uploads/2021/07/Sauna-1024x580.jpg)

![[Enjoy Kuwana! ] From Classic to the Latest Spots](https://life-designs.jp/wp/wp-content/uploads/2022/11/Kuwana_w1920x1088-1-1024x580.png)

![[Indoor Facilities] Where to Go on Rainy Days in Tokai Area! For Family Outings!](https://life-designs.jp/wp/wp-content/uploads/2023/07/FotoJet-23-1024x768.jpg)

![Onigiri is hot right now! Summary of Osu's Onigiri Specialty Shops [5 selections].](https://life-designs.jp/wp/wp-content/uploads/2023/11/onigiri-1024x768.jpg)

![[9 Selections] Summary of Retro Coffee Shops in Nagoya](https://life-designs.jp/wp/wp-content/uploads/2021/11/image1-30-1024x683.jpg)

![[Within 2hrs by Car] 12 Outing Areas where You can Go on a Day Trip from Nagoya!](https://life-designs.jp/wp/wp-content/uploads/2023/07/odekake12_w1200h900_20240422-768x576.png)

![[14 Selections] Recommended spots to spend the weekend in Kakuozan area of Nagoya](https://life-designs.jp/wp/wp-content/uploads/2022/07/Kakuozan-spot_w1920h1088_240605-328x186.png)

![[2 hours from Nagoya] From mandarin orange picking to local food and contemporary art. Recommended for autumn and winter! A day trip plan to fully enjoy Minami-Ise Town](https://life-designs.jp/wp/wp-content/uploads/2019/12/image17-7-150x100.jpg)