産地に行って服を買おう!「新見本工場」へ行ってきました。

目次

ものづくりの工程がわかる「工場見学」

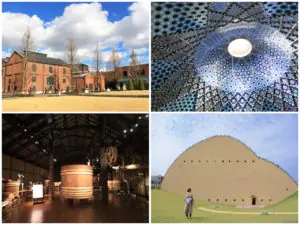

新見本工場では常設店のオープンに合わせて尾州の分業を学ぶ工場見学も行われています。尾州を知るためには「工場を見学してもらった方が早い」ということで、工場内も案内をしていただきました。

彦坂さん:「尾州では、糸から織物に至る全工程が分業制で行われています。そのため一度に、生産工程を見ることは、なかなかできません。しかし、木玉毛織ではガラ紡績機・ションヘル織機・ニットの丸編み機・縫製工場が集まっているので、さまざまな生産工程を見ることができます。

ものづくりをもっと身近に感じていただきたいという想いがあったので、「新見本工場」を常設オープンするタイミングで工場見学も随時開催することにしました。」

実際の工場見学では事務所で見学の受付をします。

※予約はオンラインサイトにて

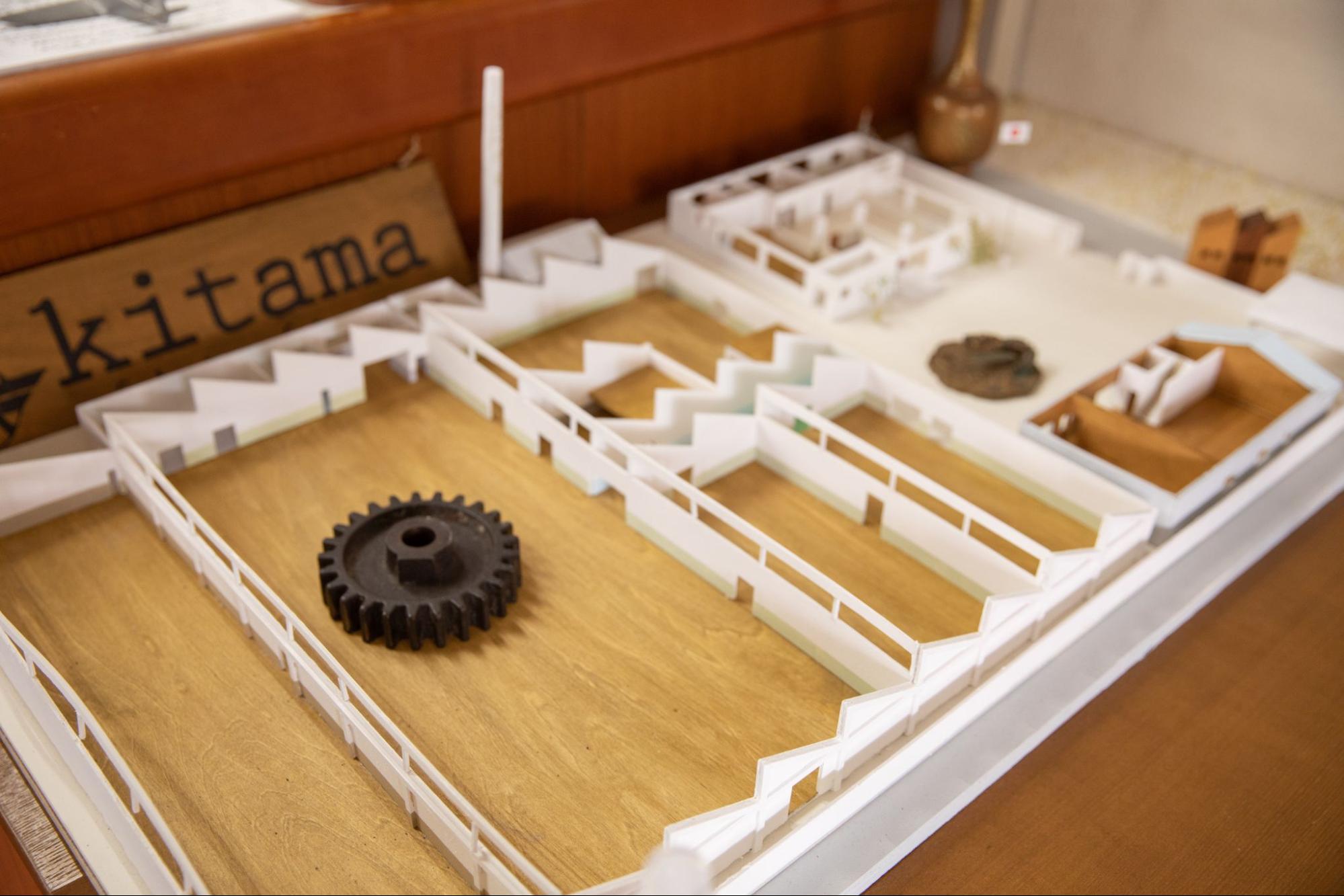

工場内の模型

工場内の模型

木玉毛織が誕生したのは明治28年のこと。かつてはウールを扱う織物工場でしたが、約15年ほど前からはガラ紡に特化した生産をされています。

他の空いたスペースは他社の工場が活用しており、そのため通常では1カ所では見られない生産工程を見学できるのだそう。

旧字体の工場の字に惹かれます。

旧字体の工場の字に惹かれます。

さっそく工場内へ行ってみたいと思います。

工場の多くがのこぎり屋根になっている理由を知っていますか?

のこぎり屋根は北向きについているため、直射日光を避けられます。そのため、1日中安定した自然光を採り入れられるので、糸や生地の色を確認するのに適しているんです。産業革命とともに急速に広まっていき、尾州でも多くののこぎり屋根の工場が現存しています。

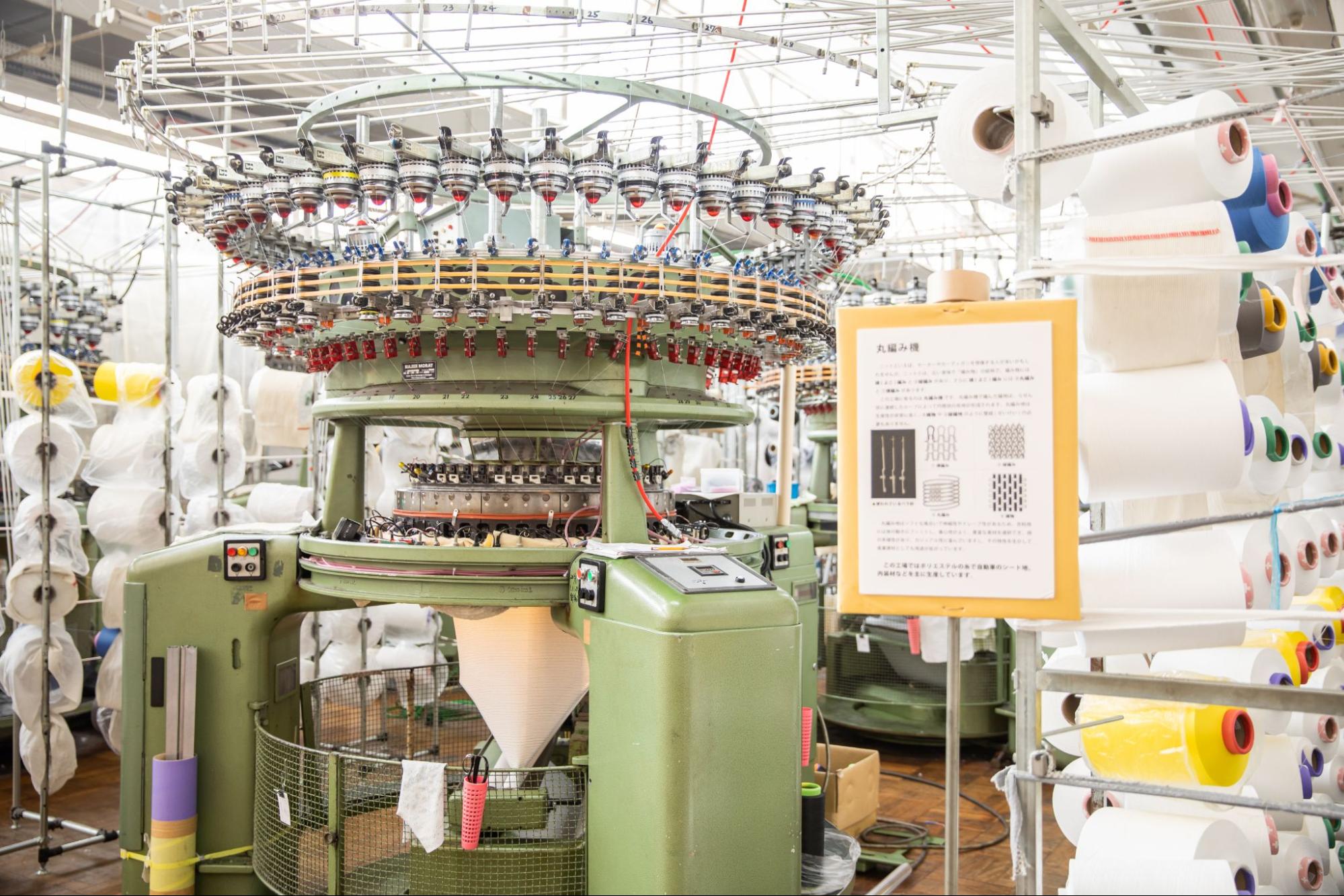

こちらはニットを製造しているところです。「丸編機」と呼ばれる機械では円状に針が並び筒状になって生地ができていきます。

できあがった編地を裁断(cut)、縫製(Sew)するので、丸編機でつくられた洋服はカットソー(cut & Sew)と呼ばれています。自分たちが普段来ている服がどんな風につくられているかって知らない方も多いのではないでしょうか。

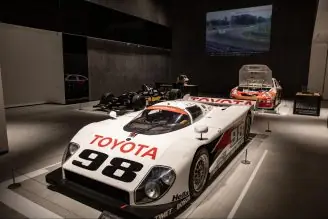

「ガラ紡」と呼ばれる機械で糸をつくっている光景です。

木玉毛織では15年ほど前から「ガラ紡」を主力にオーガニックコットン製品を手がけられています。ガラ紡とは、明治初期に考案された紡績機のことで、使用の際のガラガラという大きな音から、ガラ紡と呼ばれています。

ワタの原料の一部には、従来の高速紡績の際に繊維が短いため振り落とされる「落ちわた」と呼ばれるものをブレンド。廃棄処分となってしまうことが多い落ちわたも、ガラ紡のゆっくりとした紡績法であれば、十分に使い切ることができるのだそう。

小さな綿玉も、丁寧にほぐして大切に使用されています。

彦坂さん:「ガラ紡機を使って毎日(週5日稼働)糸をつくっているのは日本でもここだけです。現役で動いているところでも、全国で2~3件と聞いています。

犬山にある明治村さんでは展示品として見ることができるそうなので、動いているものを見れるだけでも、かなり貴重だと思いますね。」

彦坂さん:「ワタって引っ張ると簡単にちぎれますが、撚りをかける(ねじる)と伸びていくんですね。ガラ紡ではこの手紡ぎの原理を動力化しており、ワタを詰めたら、筒を回転させ上に向かってひきのばしながら糸を巻き取っていきます。

またガラ紡の糸は、太さがばらばらです。あまりに細いと途中で切れてしまうこともあるので、熟練の職人さんたちが機械のそばに立ち、調整しながら紡いでいきます。

ガラ紡から生み出される糸は、一つひとつの表情が違うところも大きな魅力ですね。」

筒状にしたワタ。これを筒の中に詰めていきます。

筒状にしたワタ。これを筒の中に詰めていきます。

彦坂さん:「工場見学では、実際にガラ紡を触る体験もしていただきます。実際にものづくりに触れることで、ものづくりの楽しさや、服をつくるにどれだけの時間がかかるのかも知っていただきたいと思っています。」

参加者にはガラ紡工場の糸でできたハンカチもプレゼントしていただけますよ!

続いては、「ションヘル織機」の工場へ。

彦坂さん:「ションヘル織機は、高速自動織機ができる前まで使われていた旧式の織機です。低速回転でゆっくりと織り上げるため、柔らかな風合いが表現できるのが大きな特徴です。この織機も60年以上使われているものです。経糸は多いときは約3000本も使います。その経糸を1本づつ筬(おさ)と呼ばれる金属のとても小さな穴に通す作業だけで1日がかり。多くても1日10m程度しか織れません。1反(約50m)を織り上げるのに約4〜5日かかりますね。」

色を変える際も一本ずつ糸を結んでいきます。

彦坂さん:「経糸が切れると、自動的にションヘル織機が止まるのですが、糸が切れた場合は、再び結びます。そして、補修工程で結び目を裏側に縫い込んで隠す職人さんがいるんです。」

最後は「縫製工場」を見させていただきました。

※通常の工場見学のコースには入っていません

彦坂さん:「ここでは、尾州のカレントのオリジナルアイテム「びしゅうのズボン」の縫製もしていただいてます。尾州産地は糸から織物、縫製までの数多くの工程を同じ地域の中で分業・協業している面白さがあります。ぜひ工場見学で尾州の素晴らしさを体感し、知っていただきたいですね。」

工場見学では、紡績・製織・縫製と複数の会社が同じ工場の中にあるので、楽しく尾州の分業・協業を学ぶことができました。

工場見学の参加者にガラ紡工場の糸でできたハンカチもプレゼント。

参加料:2,200円(税込)

▼工場見学の予約はこちらから

https://airrsv.net/kitamakeori/calendar

今回は、「尾州のカレント」の活動、「新見本工場」の魅力をたっぷりとお伝えしました。まだまだ、楽しいイベントを企画されているそうなので、今後の活躍が楽しみです。

ぜひ産地に直接行って、尾州を学び、知って、長く愛用できる一着を見つけてみてくださいね。

また、毎月第2第4水曜日夜8時からFMいちのみやで、尾州の楽しみ方を知るラジオ「びしゅうの放送室」も放送中です!そちらもチェックしてみてくださいね。