日本が世界に誇る”有松鳴海絞り”に新しい風を吹き込む「まり木綿」

目次

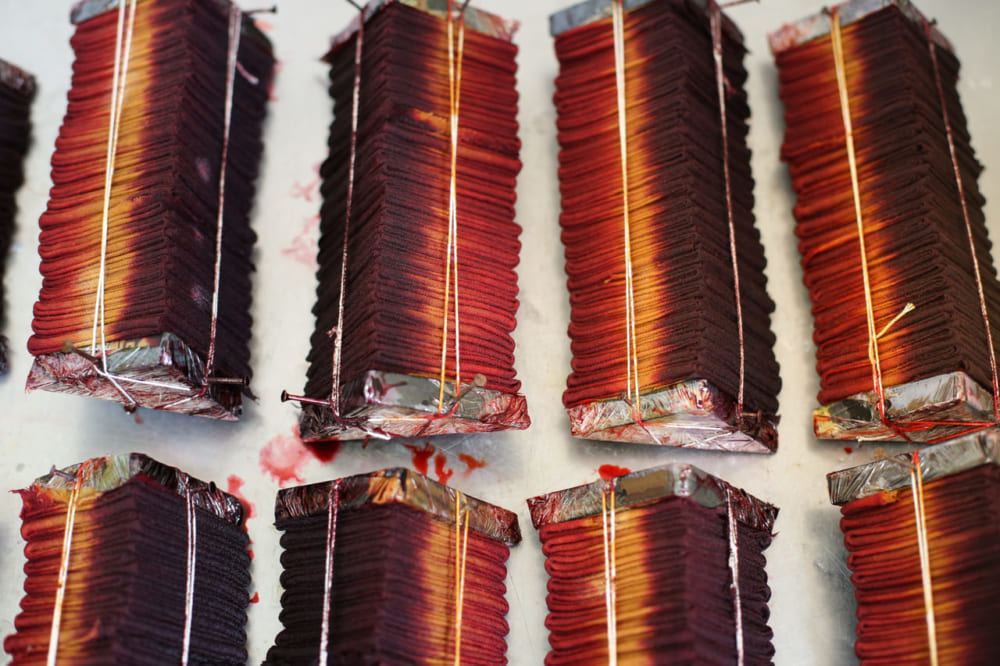

染色の様子を見学!

手ぬぐいを染めるにあたり、生地を折っていくことからはじまります。

屏風状に折りたたんだ後、端から三角形に折っていきます。

たたみ終わったら2枚の板に挟んで板締めをします。布の折り方をアレンジしていくことで、日々新しいデザインを考案されているそう。

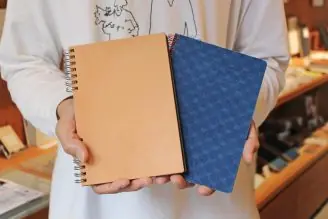

布を折りたたんだら、染料づくりです。デザインを書き留めたノートを元に染料をつくっていきます。

染料液をつくったら、いよいよ染色です!

どれくらい浸したら色がしっかり染み込むのか、浸しすぎても柄がつぶれてしまうそうなので、色に合わせた浸透率を計算しながら染色していきます。これは、まさに経験がものをいう技です。

5分もしないうちに10本近くあった布があっという間に、染め終わりました!水洗いをし、また熱湯で洗って余分な染料を落としてから天日に干すという工程を踏んで商品が完成します!

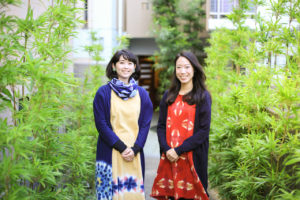

完成後はこのようになりました。伊藤さん、村口さんありがとうございました!

「今後は自分たちで専用の工場を持って、お店も開いていきたいです。」と語ってくださったお二人。帰り際、有松で別の取材をしていたスタッフと合流すると、先ほど近所の方に「まり木綿さんっていうお店がとてもすてきだから行ってみてね!」と言われたんです!というエピソードを聞き、地元の方たちにとても愛されているのを感じました。

今回取材を通して、日本の伝統を守りながらも、新しいものづくりに挑戦していく姿は一人の女性として、とてもかっこいいなと思いました。夏は暑く、冬は寒い、過酷な作業環境の中で、丁寧に一つずつ作り上げている商品はどれも、魅力的なものばかりです。伝統を残しながらも、新しい風を吹き込むまり木綿にぜひ足を運んでみてくださいね。